Online Hours

Hours displayed in:Eastern Time (US & Canada)

About

GULFSTREAM AEROSPACE

Creating and Delivering The World's Finest Aviation Experience

Gulfstream has led the evolution of business and personal aviation since the 1958 debut of the Gulfstream I, the world’s first purpose-built business aircraft.

Today, Gulfstream produces the world’s most advanced business aircraft, with innovations from nose to tail and wingtip to wingtip, all while offering unmatched global product support and service.

Gulfstream’s commitment to excellence reflects that of its parent company, General Dynamics. Headquartered in Falls Church, Virginia, General Dynamics is a market leader in business aviation; land and expeditionary combat systems, armaments and munitions; shipbuilding and marine systems; and information systems and technologies. General Dynamics’ workforce numbers more than 95,000 employees worldwide.

Gulfstream engineers, manufactures and services the world’s finest business aircraft. Headquartered in Savannah, Georgia, USA, Gulfstream operates facilities on four continents and employs more than 15,000 people worldwide.

ENGINEERING AND RESEARCH

Gulfstream designs and develops aircraft at its Savannah Research and Development Center. The five-building campus houses engineers and support staff integral to the engineering, manufacturing, testing and development of past, current and future Gulfstream aircraft. Gulfstream Laboratories features the only hemi-anechoic chamber used in the development of business aircraft. A relentless pursuit of performance, efficiency and innovation is what makes Gulfstream jets the world’s most advanced business aircraft. More than 115 Gulfstream employees belong to the American Institute of Aeronautics and Astronautics (AIAA) and approximately 25 more are members of SAE International. Gulfstream employees are also active in the Society of Women Engineers, the National Society of Black Engineers, and the Society of Hispanic Professional Engineers.

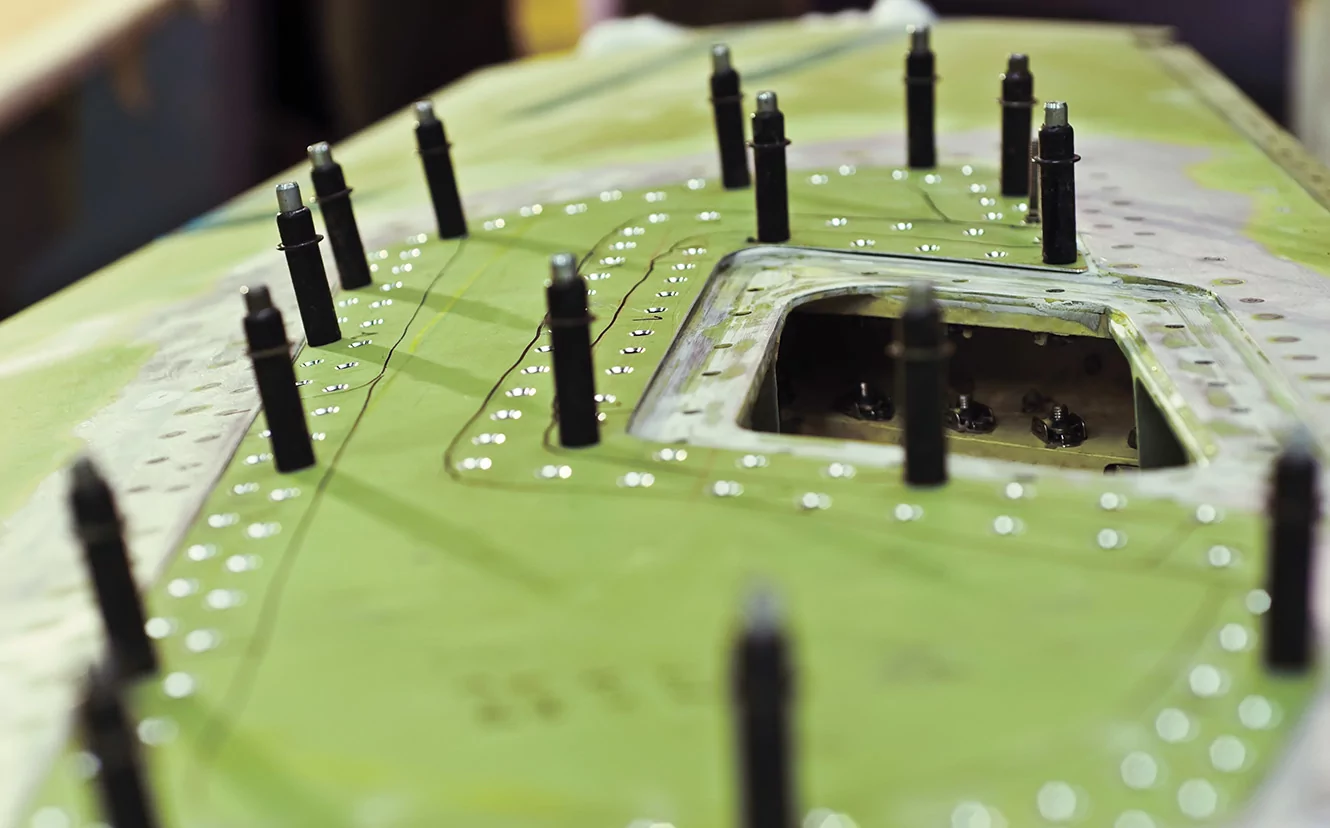

MANUFACTURING

Gulfstream manufactures large and ultralarge aircraft at its Savannah, Georgia, headquarters. The company completes midcabin aircraft at a facility in Dallas, Texas. Wiring harnesses, sheet metal components, subassemblies and machined parts are produced at a Gulfstream facility in Mexicali, Mexico. Gulfstream holds an FAA Production Certificate, counts more than 900 Lean Specialist trainees among its employees and offers courses in more than 15 different processes and tools focused on Lean and other sustainability initiatives.

COMPLETIONS

Gulfstream offers a wide array of cabin configurations. The company outfits cabins, paints the exteriors and installs avionics equipment upgrades at the Appleton, Wisconsin; Brunswick, Georgia; Dallas, Texas; Long Beach, California; and Savannah, Georgia, completion centers.

SALES AND DESIGN

Gulfstream coordinates aircraft purchases and plans cabin furnishings with buyers at Sales and Design Centers in Savannah, Georgia; Dallas, Texas; London, England; and Long Beach, California. The showrooms are stocked with myriad leather, fabric, carpet and wood veneer samples as well as dinnerware, flatware and stemware selections. Customers can work with designers and Gulfstream’s mobile visualization application, DesignBook, to experiment with various cabin configurations, colors and upholstery in real time.

PRODUCT SUPPORT

Gulfstream operates the largest factory-owned service network in the business aviation industry. The support system is anchored by 11 service centers strategically located on four continents, including the world’s largest purpose-built business aircraft maintenance facility in Savannah, Georgia. Gulfstream is also the first manufacturer to open a service facility on mainland China at Beijing Capital International Airport. Gulfstream service center personnel perform everything from routine line maintenance and complete structural modifications to engine replacement and interior refurbishment. In addition to the fixed service locations, Gulfstream has Field and Airborne Support Teams (FAST) to provide mobile support. This team of ground support vehicles and aircraft performs service remotely and can even complete an engine exchange. Gulfstream’s legendary Consider It Done attitude toward product support has earned the company top honors in Aviation International News’ survey of aircraft operators every year since 2003.